07 Apr, 2025

With the world today transforming environmental sustainability to be not a choice but a need of the day, world businesses are redesigning their way in a fresh approach to integrate green solutions. The hygiene film industry is not an exception to this. Hygiene films, and PE films specifically, have been used for decades to preserve and protect hygiene in various industries such as healthcare, packaging, and personal care. The environmental track record of conventional PE films was problematic in the recent past, and more sustainable and recyclable types were therefore in demand.

The Increasing Significance of Eco-Friendly Hygiene Films

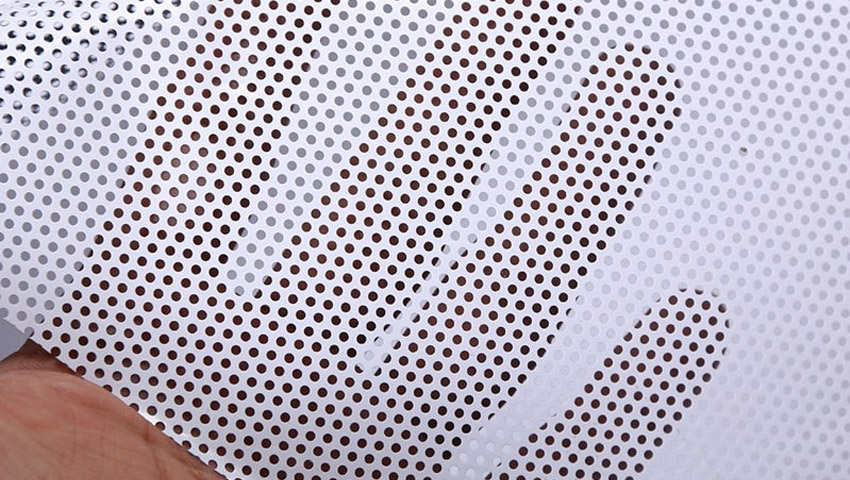

Hygiene films are flexible, thin films that are applied to guard products, surfaces, and people against contamination. They are extensively used in the medical field to sterilize equipment, food packaging to extend shelf life, and sanitary napkins and diapers. But various uses of common PE films have gone a long way in piling up a humongous amount of plastic waste into the environment, a serious environmental issue.

Today’s consumers expect sustainable products, and companies are forced to go green. This has also given a chance to create sustainable hygiene films that can be compatible with minimal environmental footprints.

The Role of PE Films in the Hygiene Industry

Polyethylene (PE) films are the basic raw material for usage in hygiene owing to their desirable barrier property, tensile property, and competitive price. PE films have an impermeable water barrier cover that prevents moisture entry as well as penetration of bacteria and other deleterious products and is hence capable of providing hygiene conditions. The conventional PE films are produced using fossil raw materials which are not sustainable and cannot get degraded and become a permanent fixture on the environmental front.

Development in Green PE Films

Made from renewable resources such as sugarcane, maize, or another biomass from vegetative plants, bio-PE Unlike conventional PE derived from fossil fuels, bio-PE relies not on non-renewable resources and has low carbon emissions. Plant sugars are fermented to ethanol and subsequently to ethylene, the precursor of polyethylene, bio-PE is produced. Apart from lowering carbon emissions, this innovative manufacturing technique guarantees better use of hygiene films.

Additionally one of the most environmentally beneficial choices for sanitary films is recycled PE. By means of collecting and processing post-consumer or post-industrial waste plastic, manufacturers can provide premium recycled PE film similar in performance to virgin PE.

Sorter and wash technology has also progressed significantly to remove impurities and make the recyclable material clean. The material is thus suitable for application use in hygiene applications. Apart from saving waste plastic manufacture, recycled PE also serves to conserve energy and inputs used in manufacturing new plastic.

Chemical recycling is a new technology in which plastic waste are disintegrated into their molecular units, and then they can be used to manufacture new plastics. Chemical recycling is unlike mechanical recycling, which relies on the plastic quality being compromised in the long run.

Advantages of Recyclable and Sustainable PE Films

There are many advantages to utilizing recyclable and sustainable PE films, both to the business and to the environment.

Sustainable PE films provide a minimal carbon footprint compared to conventional plastic manufacture. Because sustainable films are created from renewable energy and recycled raw materials, they preserve natural resources, lower greenhouse gas emissions, and zero plastic waste. This is in harmony with global sustainability targets and an environmentally friendly world.

Authorities and regulatory agencies across the globe are enacting stringent rules on the use of plastic and plastic waste management. Only those companies that utilize sustainable PE films are well-placed to comply with such rules to avoid fines and penalties.

The customers of today’s time are eco-friendly than ever before. They are asking for green and sustainably produced products. The use of hygiene films in a sustainably produced PE material enables companies to reach the green consuming market and compete with other companies in the market.

While green PE films are expensive in the short term, they are extremely cost-effective in the long term. Recycled PE films, for example, lower the consumption of virgin plastic and hence material cost. Companies can also lower their waste disposal cost using recycling programs.

Pioneer Hygiene: Green Hygiene Solutions at the Forefront

We at Pioneer Hygiene are fortunate to be pioneers in the field of hygiene film. We are green ourselves since we can produce and sell eco-friendly PE film products. We appreciate the importance that hygiene films play in making an individual clean and safe and are dedicated to providing the best in performance and the environment.

Our PE films are meant to be utilized in an eco-friendly manner to cater to a huge variety of applications from pharmaceutical and healthcare sector to food product packaging and personal care. With the most modern techniques and eco-friendly processes, we would also want to introduce our consumers with not just ways of safeguarding their products as well as customers but also how they can contribute towards the green world.

Conclusion

The future of the hygiene film is in recyclable and sustainable PE film solutions. With the globe fighting the effects of plastic in the environment, there is no choice but for the hygiene film industry to lead the way in adopting greener alternatives. Bio-based PE, recycled PE, and advanced recycling technologies are just some among the many ways to a greener future. Pioneer Hygiene is among the industry leaders in taking the lead in change with cleaner products than the conventional ones. In adopting such innovations, we can make sure that hygiene films remain an important aspect of cleanliness and security but in an eco-friendly manner.